詠浤鑫 近乎苛求的極致

EQUIPMENT

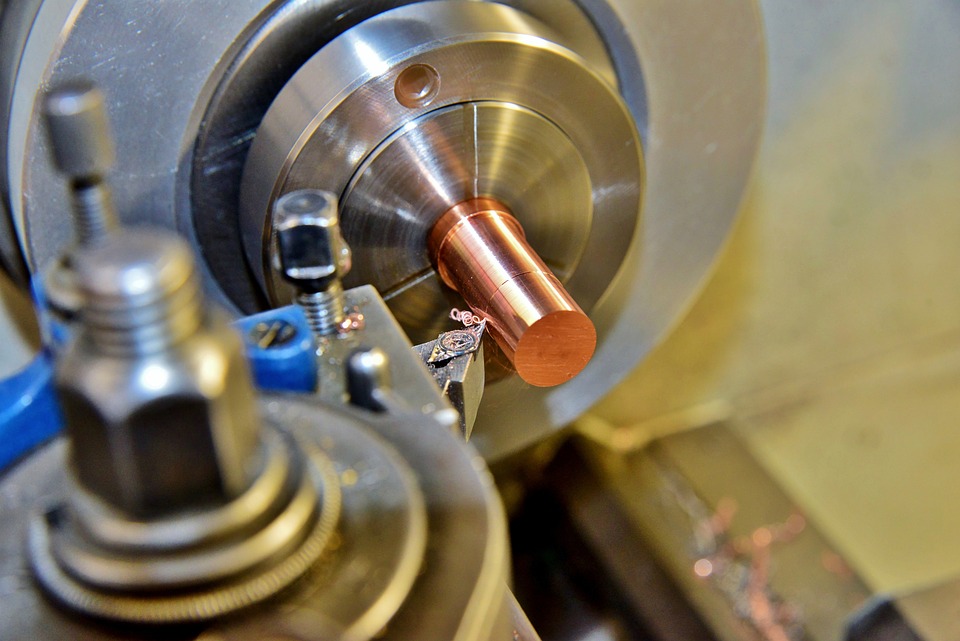

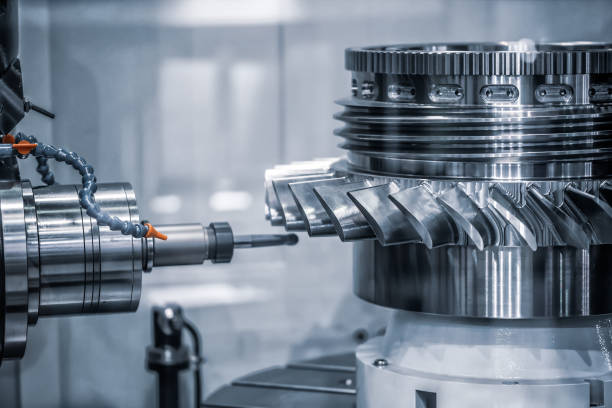

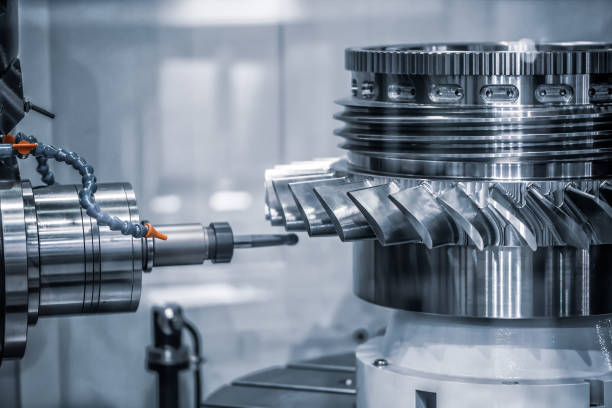

CNC MILLING

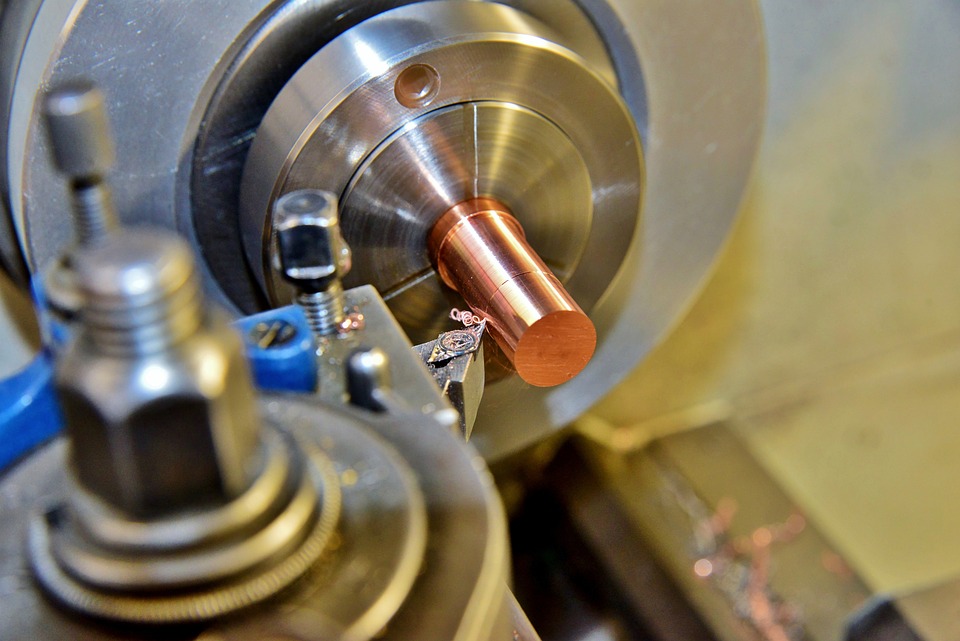

CNC TURNING

MEASUREMENT APPLICATIONS

- 3D Vision Profiler

- 3D CMM

- 2D CMM

- Height Gage

- Helium Leak Detectors

- Optical Microscope

- Portable Colorimeter

- Roughness Meter

- Other Instruments

CNC MILLING

Know more>>

CNC TURNING

Know more>>

MEASURING APPLICATIONS

- 3D Vision Profiler

- 3D CMM

- 2D CMM

- Height Gage

- Helium Leak Detectors

- Optical Microscope

- Portable Colorimeter

- Roughness Meter

- Other Instruments

Our Advantages

RA<0.1

- Provision of precision process services with RA<0.1

CHAMBER BRAZING

- Multiple technical support

- Committed to 3D cutting

- Cutting and combining different materials

BECU BRAZING

- Combination of beryllium copper (BeCu)

- Age hardening copper alloy

- Meet the exact multiple needs of the automotive, electronics and aerospace industries

GROUND PIN BRAZING

- Professional earth pin piston manufacturing

- Reliability after brazing can reach more than 99%

- Close to 100% perfect circle

CLASS 1000 CLEAN ROOM

- Reach FED-STD-209E Class 1000 clean room level of the United States

- The number of fine dust particles larger than 0.5 µm in 1 cubic foot (ft³) must not exceed 1000

- Packed specimens can be used directly in dust-free room

QUALITY MANAGEMENT

- Quality testing laboratory

- The most professional quality inspection staff

- High-precision testing equipment

- Achieve processing accuracy requirements

- Institutionalized high-standard management

OURADVANTAGES

RA<0.1

- Provision of precision process services with RA<0.1

CHAMBER BRAZING

- Multiple technical support

- Committed to 3D cutting

- Cutting and combining different materials

BECU BRAZING

- Combination of beryllium copper (BeCu)

- Age hardening copper alloy

- Meet the exact multiple needs of the automotive, electronics and aerospace industries

GROUND PIN BRAZING

- Professional earth pin piston manufacturing

- Reliability after brazing can reach more than 99%

- Close to 100% perfect circle

CLASS 1000 CLEAN ROOM

- Reach FED-STD-209E Class 1000 clean room level of the United States

- The number of fine dust particles larger than 0.5 µm in 1 cubic foot (ft³) must not exceed 1000

- The finished packing products can be directly accessed and used in the clean room

QUALITY MANAGEMENT

- Quality testing laboratory

- The most professional quality inspection staff

- High-precision testing equipment

- Achieve processing accuracy requirements

- Institutionalized high-standard management

APPLICATIONS

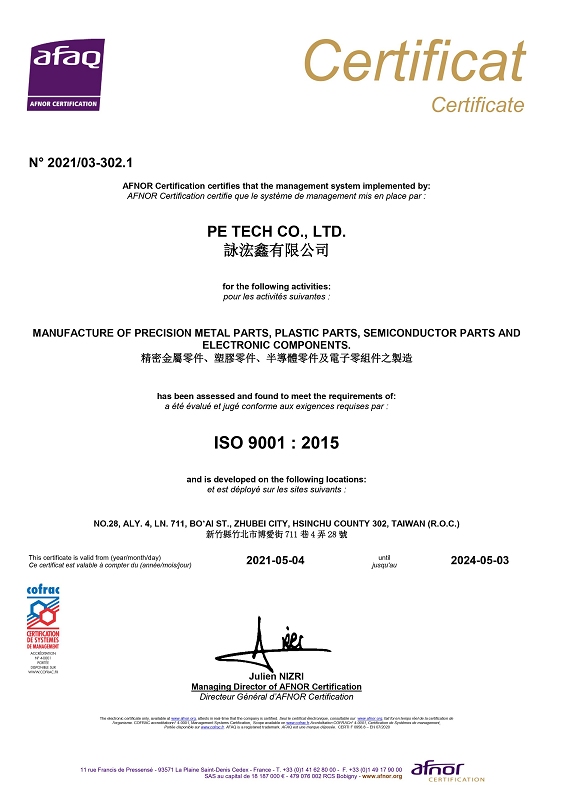

CERTIFICATE

Manufacturing of precision metal parts, plastic parts, semiconductor parts and electronic components

Passed ISO 9001:2015 quality management system verification

Passed ISO 14001:2015 environmental management system verification

An international verification standard recognized by International Accreditation Forum (IAF)

ISO 9001

ISO 14001

APPLICATIONS

Parts of Medical Biomedical Equipment System

Parts and components of Green Energy

Important parts of the vehicle industry

Smart manufacturing of metals and biotechnology, food and medicine

Manufacturing of precision equipment components

High-value metal products

Precision machinery products

Precision molds, knives, tools

BOOKING NOW

Focus on the design and manufacture of various parts through the technology of high-quality heterogeneous material combination. Further provide FED Class 1000 clean room grade packaging and shipment. It is especially suitable for semiconductor equipment, biomedical equipment and other fields that require a dust-free environment. Please do not hesitate to contact us to understand your service needs.