Technical ADVANTAGES

-

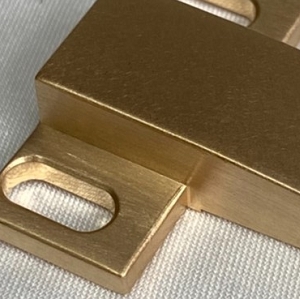

Professional brazing technology process

-

High-quality technology for combining different materials

-

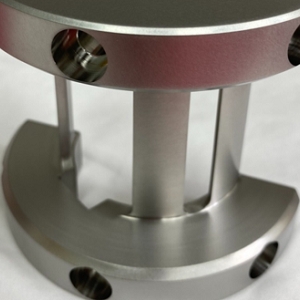

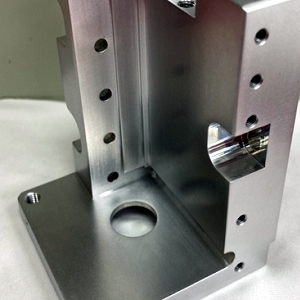

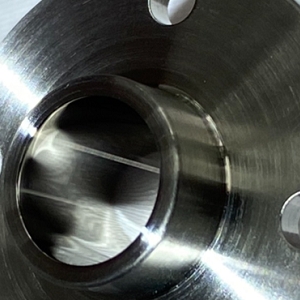

Design and manufacture of various precision parts

-

Application of Molybdenum Metal

-

Shorten the polishing time of Ra0.1

-

The precision can reach 0.01

-

3D and the leaking rate is extremely low

-

Reliability of finished product ≧ 99%

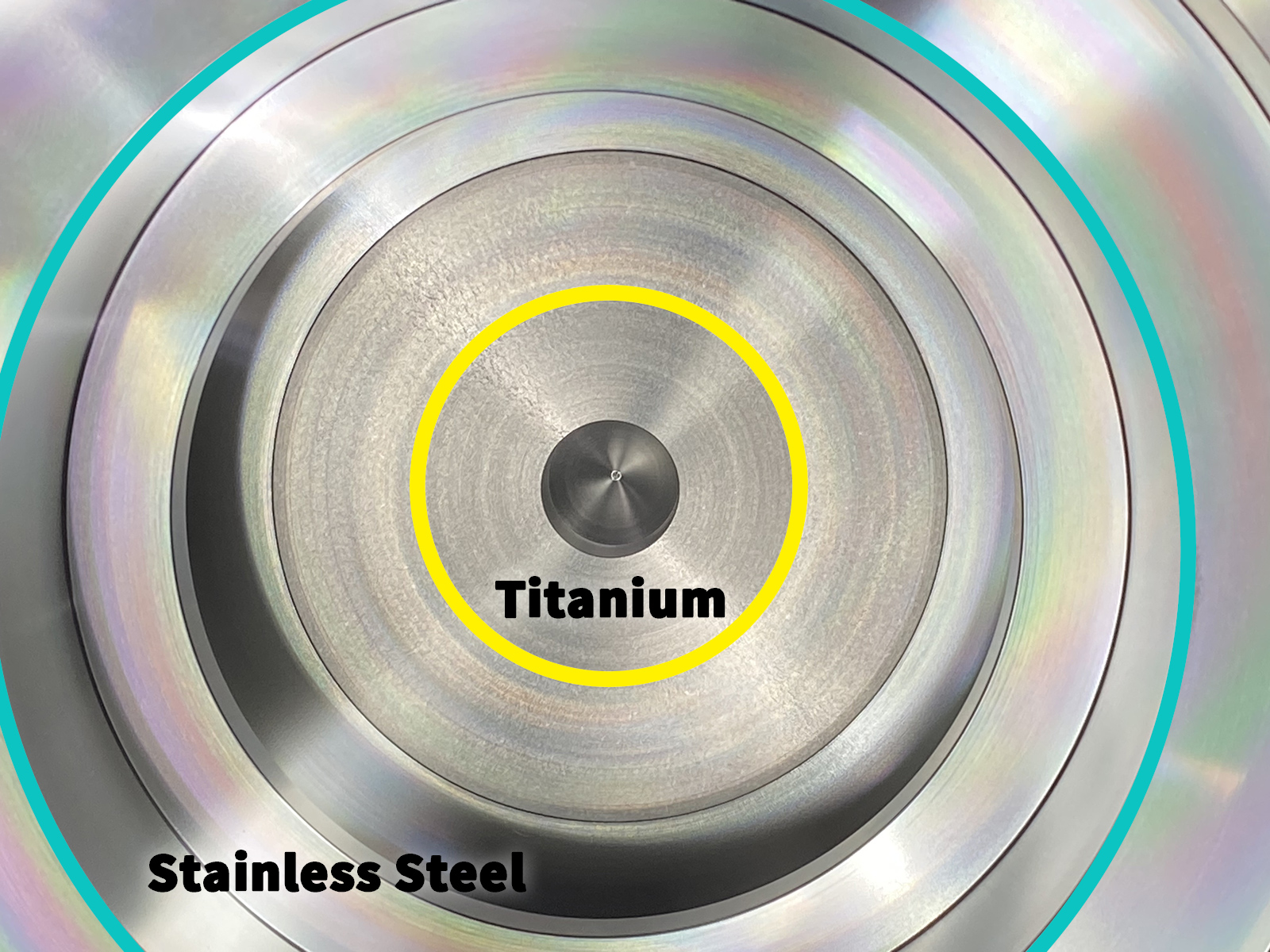

Process characteristics of

Special Brazing Technology

Directly Combining Different Materials

- Oxides, nitrides, various ceramics, metals

- Active metals including titanium, etc.

- Increase the wettability of ceramics

- Heating and bonding are performed at one time, thereby reducing man-hours and delivering as soon as possible

Process optimization, improve yield and quality

The brazing of different materials combined with the milling and cutting of the curved surface o-ring, the vacuum leaking rate can reach 1.00E-12 as quickly as possible

Machinable Material

Stainless Steel

Beryllium Copper

Glass Fiber

Aluminum

Moly Ra≦0.1

Phosphor bronze

Titanium Ra≦0.1

HyMu80